Innovation

We value ingenuity and exploration.

Studio NYL is never constrained by what’s been done in the past. We stay at the vanguard of emerging techniques, approaches, and technologies and share our intellectual capital openly with clients, each other, and the broader industry.

How we innovate

Systems

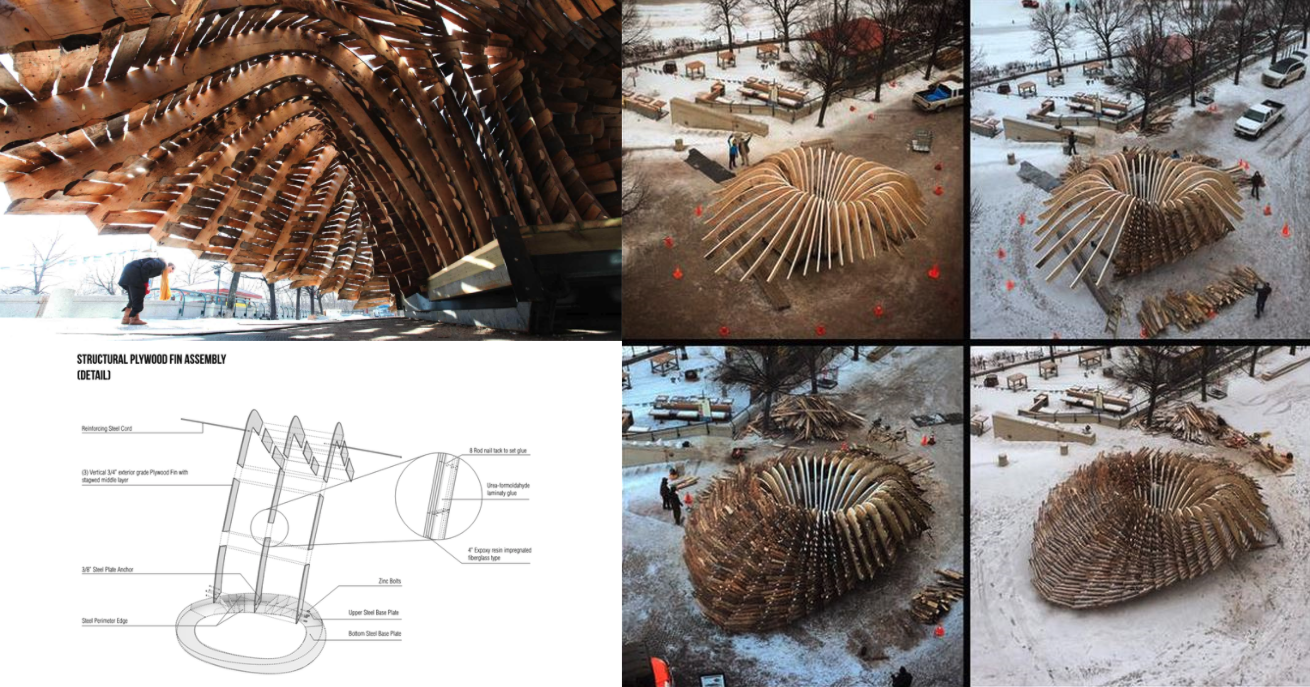

Studio NYL’s diverse team has experience with a wide range of systems and we are always looking for new ways to unlock their potential for efficiency and geometric interest. We work creatively with form and material strengths to achieve a project’s vision.

Materials

We have a vast library of materials we work with and are constantly adding to it. We pride ourselves in using ‘conventional’ materials in unconventional ways, such as rammed earth structures, terra cotta, carbon fiber, and more—testing, analyzing, and documenting what can meet our partner’s aesthetic and performance needs.

Technology

Studio NYL’s computational design capabilities were born from the need to maximize efficiency and exploration in designs and the design process. Our ability to merge form and analytics—and represent them graphically—has made some of our most successful projects possible. We are constantly stretching our capabilities crafting custom algorithms and scripts to help our team and partners stay on the leading edge.

Research and development

We invest heavily in exploring new ways to make great design happen through R&D in process, materials, and techniques. Examples include:

Terra cotta research: in collaboration with Boston Vally Terra Cotta, SUNY Buffalo Architecture School, mOrphosis, Sasaki, HKS, and Adrian Smith Gordon Gill

Flexible wood joinery research: in collaboration with MakeLab Sasaki, and The University of Colorado, Boulder

Rammed earth and compressed earth block research: in collaboration with Pyatt Studio and the University of Colorado, and the Mortenson Institute for Developing Communities

Perforation studies: developing a testing regime to dynamically load perforated panels to justify windload reductions.

Resources